Hot Water Cylinders

There are basically two types of hot water cylinder, gravity and pressurised (unvented). Within this they can be heated direct or indirect. There are advantages and disadvantages to both types, in some cases the type of property will dictate the type of cylinder you will have due to location or space issues. Factors in deciding this will include incoming mains pressure, and flow rates, access to loft space, is there even is a loft space? Ease of installing safety blow off pipe as laid down in the G3 Building Regulations

In-Direct

This is when the cylinder is heated from another source via a coil built into the cylinder. Other sources could be a gas or oil boiler, a heat pump, bio-mass, solar thermal panel on property roof, range cooker.

The coil is designed to exchange heat from the boiler etc. but at same time stop the water from the mixing from heating system as will contain contaminants such as inhibitors, and you would want to wash with this.

Direct

No coil built in, the most popular way for direct is heated via electric immersions, commonly two in one cylinder, if a particular large cylinder it can be three immersions. These could be linked to an economy 7 system in property so gets the benefit of cheap night time electricity, as modern cylinders and usually well enough insulated for it to retain the heat throughout the day.

The lower immersion would be wired for night time to heat the

whole cylinder, whereas the top immersion would be wired for a day

time boost. Alternatively on some old systems a range cooker heats

the cylinder directly into the cylinder, yes sharing same water, as

no coil. More often they would also have a heat leak attached to

system in form of a radiator as there is no way of controlling the

built up of excess energy, and if left untapped could prove

dangerous.

Open Vented (Gravity)

This type of cylinder is gravity fed via a storage tank of water which must be above the cylinder. The higher the tank, the greater the pressure, 1 Metre head equals 0.1bar (some shower will fail to operate on such low pressure). You can calculate the working head (pressure) by measure the height from the outlet (e.g. shower head) to the base of the storage tank in attic.

In order to vent the cylinder when filling and to accommodate the expansion of the water when heated, an open vent to atmosphere terminating above the cold storage tank is installed. The cold storage tank is usually sited in the roof space. Obviously this roof space is not always available e.g. in a flat.

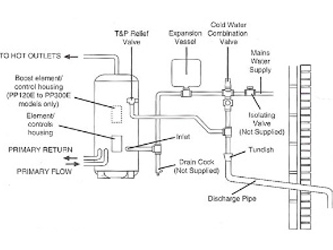

Unvented

Unvented hot water cylinders store water supplied directly from the mains water supply, and heat it using either electrical heating elements or with heat from a boiler. This provides high pressure hot water supplies capable of feeding outlets with high flow rates of hot water. The cylinders store water under relatively high pressures 2 bar upwards, this is depended on the mains cold water supply. The increased pressures also make for more powerful showers, without the need for mechanical pumps.

As hot and cold water supplies are fed from the mains there is

no more need for a cold water storage tank, keeping loft spaces

clear, and pipework to a minimum, and less chance of frost damage,

also reduce heat loss normally associated with the pipework in

attic.

The Advantages of Unvented Cylinders

1. High pressure system.

2. No pump required, means no noise or another item to break.

3. No need for cold storage tank in attic.

4. If stainless steel, has long life span.

The Disadvantages of Unvented Cylinders

1. Relies on mains pressure.

Mains Water Supply

Ultimately all the property supply is driven by the incoming mains pressure, yes there is ways around to resolve some issues with mechanical devices such as pumps, however this is potentially another moving item that will need attention or repair. As a general rule you need a minimum of 2 bar working pressure consistently, more is better thou, but the flow of water is just as important, some which is usually overlooked. If the pressure is too high a Pressure Reducing Valve should be fitted on incoming mains, consider this above 5 bar pressure. Remember most WRAS approved products will fail or break when approaching 10 bar. The difference between pressure and flow is important to understand - a mains water pressure of 6 bar is no good if it is supplied through 90 metres of old ½” lead supply pipework. Mains supply pipe sizes and flow rates, as well as pressures, must be checked.

Materials

Unvented cylinders are typically made from copper, stainless steel, or glass lined steel. Each has its benefits, and the type of cylinder to be used will often depend upon the application.

Copper: Used extensively to manufacture domestic water cylinders, mainly because it is easy to cut, shape, fold and braise, and it is very easy to add additional bosses or make one of special cylinders. Copper unvented cylinders will usually have a operating pressure up to 2 bar.

Stainless Steel: A much stronger material than copper, and is capable of withstanding higher pressures. Such cylinders typically have an operating pressure around 3 bar, but designed to take pressure up to 10 bar. Stainless steel is also highly resistant to corrosion giving it a greater life expectancy. Rare, but welds may be susceptible to corrosion from alkaline water. It is not usual to get manufacturer’s warranty of 25 years on stainless, giving an indication of the quality of the product.

Glass/Enamel Lined Steel Cylinders: Made up of a mild steel cylinder that is coated on the inside with a layer of glass (similar to the enamel coating on a bath) to provide resistance to corrosion. Cylinders typically have operating pressures in the region of 3.5 bar, but can often take far higher pressures. These types of cylinders are cost effective, typically being mass produced on the continent and in the USA. The glass lining around bosses can crack, so extra care need to be taken and it is wise to check that primary coils are supported to avoid movement during transit that may stress and possible crack the glass lining. Cylinders should always be fitted with powered anodes to further protection from corrosion. These cylinder are quite rare in UK.

All types are sold in the UK. Historical the copper open vented cylinders have been used, but the trend is now moving to stainless steel unvented (pressurised), due to great flow rates through the property and the longevity of the product life.

Expansion

Unvented cylinders still need to provide the same as vented cylinders to accommodate the expansion of the water in the cylinder as it heats up. As water is non-compressible the pressure will rapidly rise. In some countries this phenomenon is used to control expansion in water heating systems and is known as 'expansion to waste'. Under UK Water Regulations, this is not allowed and with unvented cylinders, it is necessary to allow for this expansion within the water heating system. In the majority of unvented systems the expansion is accommodated by providing an 'expansion volume' and again this differs between manufacturers, as it is either provided internally within the water heating cylinder (commonly termed 'bubble top' system) or the most popular method through an external expansion vessel (a trapped volume of pressurised air, held by a rubber membrane built into the vessel).

Safety Requirements

There are two main dangers that unvented systems must address. First is over-pressurisation, caused by a failed pressure reducing valve, or by backpressure, from a faulty mixer valve e.g. a kitchen tap. The other is overheating, if an unvented cylinder should ever overheat and reach 100°C, then instead of boiling away as it would with a vented system, the water will continue to rise in temperature and pressure until the cylinder can no longer hold the pressure and splits. At this time, the sudden reduction in pressure resulting from the split may cause water to 'flash' rapidly to steam. The higher the pressure at failure the more steam, and cylinders capable of taking higher pressures will fail more dramatically or even explode. Take into consideration 1 litre of water when turns to steam will produce 1600 litres in volume, so a small 120 litre cylinder of water if failed in a dramatic fashion could produce 192,000 litres of steam.

To prevent this from ever happening, there are safety requirements that have to be carried out. A ‘Pressure Reducing Valve’ (limits incoming water pressure), ‘Expansion Relief Valve’ (allows water to be discharged during heat up if the means of expansion has failed to operate). Both of these valves are often combined into a single inlet control device. A ‘Temperature and Pressure Relief Valve’ (allows water to be discharged when stored temperatures or pressures start approaching unsafe levels). Any water discharged in this way will typically be replaced by incoming cold mains water that will prevent store temperatures from rising further. When the water is discharged this is done through a ‘Discharge Pipe’, first passing through a visible/accessible ‘Tundish’. All cylinders installed must be installed as per manufactures instructions and comply with the current G3 Building Regulations. All work must be carried out by a suitably qualified person with these up-to-date qualifications. These cylinders and all the attached safety devices should be subject to an annual service/inspection.